An interview with Mr. K. R. Vijayan, Founder and Chairman, Good Leather Group

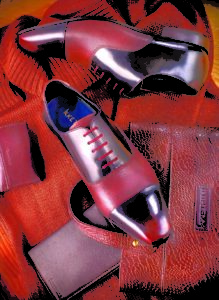

Good Leather Shoes Pvt Ltd was started in 1994 by making shoe uppers and since then it has grown to be Rs.120 crore company, manufacturing shoe uppers, full shoes and bags. With a capacity to manufacture 2000000 pairs of shoe uppers and 2000000 pairs of full shoes per annum, Good Leather exports all its products to reputed buyers in Europe, UK and USA. Equipped with the latest technology and employing around 1600 people, the group is also planning to make its presence in the local market and is in the process of developing their own brand by name Kethini. We spoke with Mr. K. R. Vijayan, Founder and Chairman, Good Leather Group to learn about the Indian finished leather industry and the importance of skill development and related topics.

Please tell us about Indian finished leather industry in terms of its scope for employment and exports.

Please tell us about Indian finished leather industry in terms of its scope for employment and exports.

Indian finished leather industry focuses on exporting value-added products. To meet the increased demand by product manufacturers, the finished leather processors are keen to improve skills to produce higher volume of good quality through employment of new techniques, development of new types of leather and reduce cost. This enhances the potential to export larger volume of products with finished leather exports getting limited to high grades, lining and stock lots of different assortment. The Industry is progressively employing machinery with new and added technical features to improve efficiency, reduce cost and produce volume. The scope for employment does exist in an indirect form that the increased volume and quality assists product manufacturers to add capacity and further investments. Being labour intensive, the product manufacturers significantly contribute to employment generation. Add to this, the restrictions by the supreme court to establish new tanneries restrict capacity.

How does IFLMEA cater to the needs of the business community in the Finished Leather sector?

IFLMEA shares market information from a centralized desk. This includes price factors affecting the industry, especially on sourcing from different geological locations, analytically derived by experts is shared regularly with members through e-mails and newsletters. It also conducts seminars chaired by eminent achievers in the respective field on fresh issues affecting the industry, thereby acting as a bridge between the Industry and connected government departments through Council for Leather Exports (CLE). Members can also get Leather Working Group (LWG) certification through coordination with IFLMEA.

We created awareness with the help of CLRI /CSRI on the need to be conscious about the effects of pollution and effluent release and the means and sources now available to avoid and reduce the same. The manufacturers were advised to support CSR initiatives of the government by creating a green environment in their area of operation. They are also advised to employ only such technology that ensures a healthy ecosystem being developed and maintained.

What are some of the key areas in the footwear industry, particularly in MSME sector, where we need support for skilling their workforce?

What are some of the key areas in the footwear industry, particularly in MSME sector, where we need support for skilling their workforce?

There are established institutions run by both public and private sector that provide the MSMEs with basic knowledge. The manufacturers avail this opportunity and draw workforce from such institutes and then train them in all aspects of the manufacturing process. Later, they are are assigned to specific tasks and they get trained in specializing with expert help. This is followed by a rewarding job and a career in the industry. However, there is a need is to support the manufacturers from MSME sector in execution through concessional access to such efforts by the government in the form of creation of facilities, funding of efforts by manufacturers and offer of subsidies.

The Good Leather Group employs all indicated measures and ensures that every worker is satisfied. The Group adopts most suited strategy for each activity and follows the basic principles to ensure that the right workforce forms a good team, reduces attrition and produce and sell as planned. The group , thus far, had gone to campus recruitments only from reputed institutes. The new recruits are reviewed for performance over a period of six months of probation before confirmation.

How do you meet international quality and standards for all your products? What are some of the compliances you adhere to?

The standards can be classified into two main components. One is generally associated with the product, at the international level. The other is specific to the buyer and his country. The restrictions mainly relate to use of chemicals and materials in the process both universal and specific to the country of buyer. We first segregate these two immediately on receipt of preliminary enquiry. The standards that can be met within and those that require outside assistance are bifurcated. The outside support will be in the form of lab assistance, certifications by designated authority and prior notifications through intermediaries. These are first put in place, cost and time determined before accepting the offer and price quotes. The buyer needs are studied by an expert team from all those involved. Sampling to finished product is studied in depth and proper checks and balances put in place before commencement of production.

Please tell us about the impact of new technology and automation in the industry.

Please tell us about the impact of new technology and automation in the industry.

Technology evolution is a continuous process. The communication system available today allows access to every new development immediately. All you need is to be aware and the effects it will have in the immediate present and over a period of time. Depending on its effects on you and the impact when competition will cause by its increased deployment will decide your action. Good leather group adopts a policy of maximum retention of profits in business. This assists in investment in new technology, develop skilled workforce and replace and balance existing machinery. We also adopt to new technology and readily introduce semi-automatic machines wherever possible. The need to continuously invest and stay ahead of competition drives this need. Good governance and financial disciplines help in becoming very resilient.

What is your advice to new entrepreneurs in this sector?

We heartily welcome every new entrant. There is scope , market and space for each one. The only need is to invest after a proper study that is all encompassing. Being a basic biological product, a thorough knowledge of what it implies to invest in this field is a must. The location, the market, the raw material availability, labour source, release of effluents, treatment of effluents, government approvals, pollution control and the proposed product need to be taken into consideration and the hypothesis documented. Ethical practices and an open mind will be essential. A platform to objectively review project progress is necessary. Given the above, all new entrants who adhere to basic business principles are sure to achieve their goals.

How do you CSR initiatives improve the workplace?

All our factories are surrounded by greenery. We use solar power and all our sheds are constructed to facilitate natural lighting. We avoid the use of plastics in every form. All our toilets are kept clean and hygienic. We actively participate and contribute to every eco-friendly activity in the community adjacent to our factory.